On our Facebook page, we are regularly publishing images from our Cavriago construction site, where we are building two Passive Houses.

With this article, we would like to show just two examples of the many construction errors that can occur during the scope of the works, even working with an accurate contractor, proving that careful site supervision is necessary to meet a high level of quality and efficiency.

The detail we are going to write about is the perimeter of the foundation of the thermal envelope. The foundation itself is a concrete slab sitting on top of a drainage layer made of cellular glass gravel. On the sides, the slab is insulated with a panel of cellular glass.

No matter what calculations or drawings are made during the design phase, such a delicate detail of the thermal envelope cannot be left to be executed without supervision.

In the case of our site in Cavriago, the work was executed very well, with a separation layer of polypropylene geotextile between the glass gravel and the concrete (see the white strip in the picture below).

PROBLEM #1: CONCRETE LEAKS

In some isolated spots, the concrete leaked out from underneath the formwork panel, as you can see in the image below.

This is no doubt a thermal bridge. Is it a bad one? It depends. If you are building a Passive House, these details matter a lot.

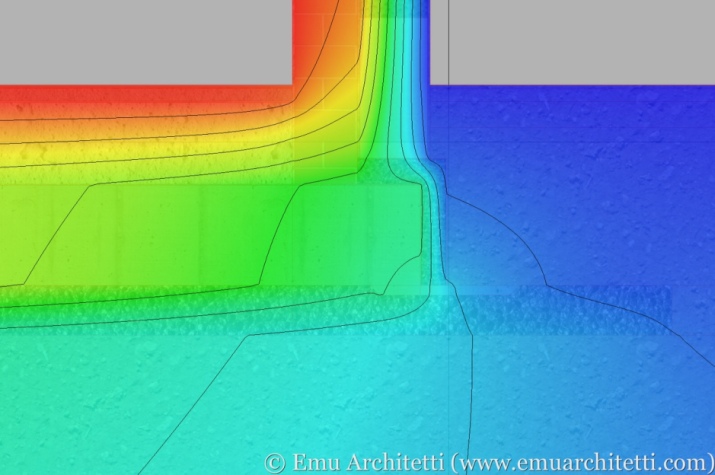

We calculated the effect of this thermal bridge, using a finite element software:

According to our calculation, the concrete leak as shown would increase the heat flow through the detail by approximately 4,2%. Calculating the sum of the (few) leaks along the perimeter, it would bring an increase in net energy demand of the whole building of a full 1%. Is this a lot? For a passive building, it is.

When considering comfort, on the other hand, if this error is a few isolated spots (not continuous), it does not have a real effect on the indoor temperature.

PROBLEM #2: HOLES TO FIT REBARS

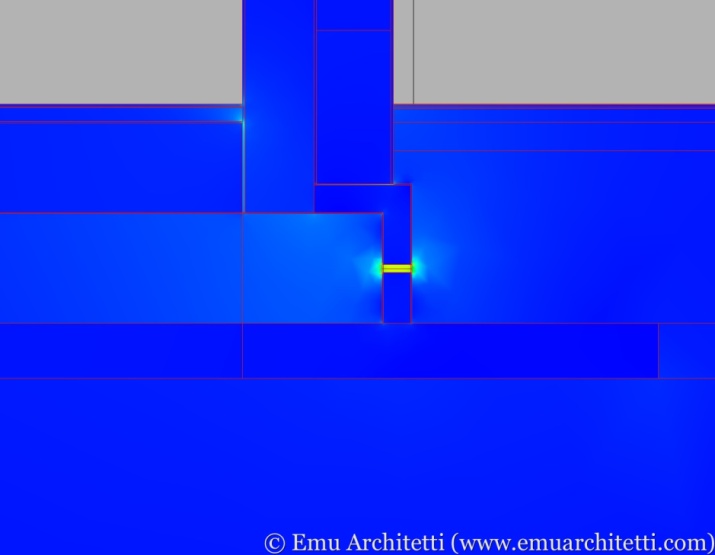

Another risk for unexpected thermal bridges is given by the holes made through the vertical insulation panels to allow rebars to connect the (warm) foundation concrete slab of the house to the adjacent one of the garage (not yet cast at the time the photos were taken).

The hole cut through the panel is about 30 mm high: if we sum up the individual lengths of these cuts along the perimeter of the foundation, the total amount reaches 7,20 m.

Again, we calculated how bad it would have been if we had left this detail to the business as usual (BAU) practice to fill this void with standard concrete.

If not avoided, this BAU construction mistake would have increased the heat flow through the node by 4,6%, with an increase in the net energy demand of the whole building of 1,6%.

CONCLUSIONS

The higher the goal, the better the execution needs to be. This relies first on high quality design, and then on attentive site supervision.

In one single day of works, we risked making the whole building envelope 2,6% worse than designed. And we are just at the foundations of the building.

This is not necessarily the contractor’s fault: building is difficult. Among Client, Architects and Contractor there needs to be an understanding to maximize teamwork and communication. Whoever is in charge of site supervision needs to be present, and aware that these kinds of problems can happen and do matter.

5 comments